Michigan Scientific Wheel Torque Transducers are ideal for measuring wheel torque on passenger cars, light and medium duty trucks, Class 8 trucks, agriculture equipment, and construction equipment.

Features

Michigan Scientific Corporation designs and manufactures highly sensitive Wheel Torque Transducers to measure drive and braking torque. The transducers are attached to adapters that duplicate the critical dimensions of the original rim and hub. Due to the high strength material and weatherproof sealing, the transducers can be used under normal driving conditions. Precision transducers are useful for gathering data in brake systems, vehicle stability, and driveline development. Michigan Scientific Mass, Force, and Weighing Devices and Mechanical Calibration is accredited to the ISO/IEC 17025:2017 standard. The design, manufacturing, and calibration process of the Michigan Scientific Corporation Wheel Force Transducer, Wheel Torque Transducer, and Load Cells is certified to the ISO 9001:2015 standard.

With Michigan Scientific High Resolution Wheel Torque Transducers it is possible to measure aerodynamic drag, brake drag, tire rolling resistance, and bearing seal drag in on road testing. Model TW12.8HRMS175 can be used to test cars and SUVs and resolves 0.1 N-m, while model TWHR2000 can be used to test commercial trucks and resolves 0.8 N-m. High Resolution Wheel Torque Transducers are commonly used for on-road measurement of chassis system losses which influence fuel economy. It is the ideal tool for fuel regulation testing.

Documents

Calibration

We have spent years perfecting our unique, patented transducer calibration machine, the TCAT. A calibration compares the electrical output of a transducer to the applied loads. The TCAT can calibrate all MSC multi-axis load cells, Wheel Force Transducers, and Wheel Torque Transducers. The TCAT applies loads with linear actuators and measures the load through the transducer via reaction links. It applies three forces and three moments and calibrates through each transducer’s unique electronics package. In addition to the TCAT, MSC has a large calibration that uses hydraulic arms to apply forces and moments; up to 100,000 lbs.

The Michigan Scientific transducer calibration process complies with ISO 9001:2015 and ISO/IEC 17025:2017 requirements and all reference measurement equipment is traceable to National Institute of Standards and Technology (NIST). It is recommended that customers send in their transducers after one year of use, and then every two years after that. This is an easy way to ensure that the transducer is functioning properly and has not incurred any damage during use.

With the development of the patented transducer calibration machine, calibration time has significantly decreased, allowing for a faster turnaround and return to customer. There are multiple locations throughout the globe to get a Michigan Scientific transducer calibrated. The calibration process is now also automated, which allows our highly skilled technicians to focus on transducer design and manufacturing improvements.

Applications

Related Blog Posts

Standard Models

4,000 lb-ft capacity

Adapts to 10" and larger wheels

4,000 lb-ft and 6,000 lb-ft capacities

Adapts to 14" and larger wheels

7,000 lb-ft capacity

Adapts to 15" and larger wheels

7,700 lb-ft capacity

Adapters to 12" and larger wheels

15,000 lb-ft capacity

Adapts to 16 inch and larger single or dual wheels

50,000 lb-ft capacity

Adapts to 19.5" and larger wheels

60,000 lb-ft capacity

Adapts to 19.5" and larger wheels

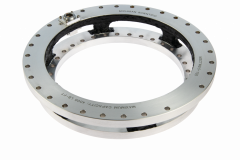

High Resolution Models

0.2 lb-ft Accuracy

175 & 800 lb-ft Measurement Range

6,000 lb-ft Capacity

Adapts to 14" and larger wheels

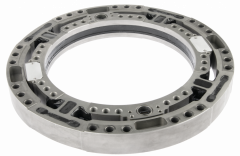

20,000 lb-ft capacity

Adapts to 22.5" rims and larger

Last Modified: