Instrumentation for force, torque, strain, temperature, angular speed and position, and acceleration measurements.

Instrumentation for force, torque, strain, temperature, angular speed and position, and acceleration measurements.

The Design, Manufacture, and Calibration for Wheel Force Transducers, Wheel Torque Transducers, and Load Cells is certified to the ISO9001:2015 standard. Mass, Force, and Weighing Devices and Mechanical Calibration is accredited to ISO/IEC 17025:2017 standards.

The SW-SR2 Steering Wheel Torque and Angle Transducer is capable of measuring the steering wheel torque, steering angle, and steering velocity on a full range of vehicles. SW-SR2 has a ±1440 degree multi-turn encoder and both Analog and CAN signal outs. It can mount to the existing vehicle steering wheel or replace the steering wheel by mounting directly to the spline steering shaft.

MSC Three Directional Load Cells are ideal for measuring forces and moments. With high accuracy, wide range of capacities, and small size, these load cells are used in a wide variety of applications. Applications include measuring engine and motor mount forces in a vehicle, vehicle suspension forces, and test bench reaction forces. Rugged housing and temperature compensation ensure results in challenging conditions.

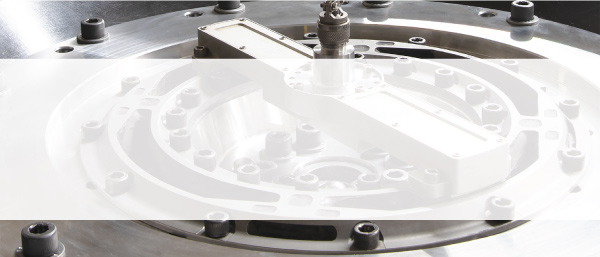

Wheel Force Transducers (WFTs) are used to measure vehicle reaction forces during durability and vehicle dynamics testing. MSC WFTs are known for their durability, accuracy, simple installation, and ease of use. Installed on cars, SUVs, all sizes of trucks, ATVs, agriculture equipment and construction machinery, MSC has a wide range of WFT capacities to fit almost any wheeled vehicle.

The utility of MSC’s instrument quality slip rings is unparalleled. The S-Series Slip Ring is capable of unlimited bandwidth and high-speed r/min. MSC slip rings transfer signals in the harshest of conditions. They provide low-noise rotating connections for various sensors including strain gauges and thermocouples.