Michigan Scientific Corporation (MSC) high-quality Extended Life (EL) slip ring assemblies provide a long-lasting solution for the development and validation of rotating equipment and machine components.

The he SR36M/EL2 is designed to mount on the end of a rotating shaft and make connections to strain gauges, accelerometers, and other sensors, providing clean and quiet signal transmission for accurate and dependable data acquisition during durability, fatigue, and endurance (R&D) testing. The SR20M/EL2 and SR36M/EL2 excel in high-speed and industrial applications where continuous transmission of data signals is critical. MSC long life slip rings help companies avoid costly downtime. Typical applications for Michigan Scientific EL end of shaft slip rings include:

Instrumentation of large-scale test stands for automotive, heavy equipment, marine, aviation, and aerospace subsystems.

- Four (4) square test cells for powertrain and drivetrain component testing

- Dynamometers (dynos) for internal combustion engine (ICE) testing (gasoline and diesel engines, vehicles, ships, generators, etc.) measuring load conditions and torque to ensure that the engine is operational and safe

Reliable long-term signal transmission for testing and data collection on continuously rotating equipment across industries.

- Industrial machinery and automation equipment

- Wind turbines

- Large fan and blower systems

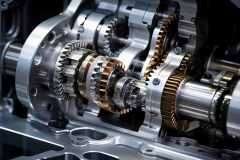

- Gearboxes

- Industrial generators and compressors

- Commercial and military aircraft components

MSC technology allows our clients to accurately and efficiently test and launch new products that meet and exceed safety and performance standards. With no signal or bandwidth limits, MSC EL slip rings are ideal for continuous rotation applications that require a reliable long-lasting solution.

Contact our team of experts at MSC to create your best technical solution.