In 1975, the United States Congress enacted the ever-changing Corporate Average Fuel Economy (CAFE) regulations to improve the average fuel economy of cars and light trucks. Similar fuel economy regulations are also enforced in foreign countries. These regulations may change so that vehicles must meet a certain efficiency by a scheduled year. During vehicle development, extensive testing needs to be done by auto manufacturers in order to determine any powertrain losses that influences fuel economy.

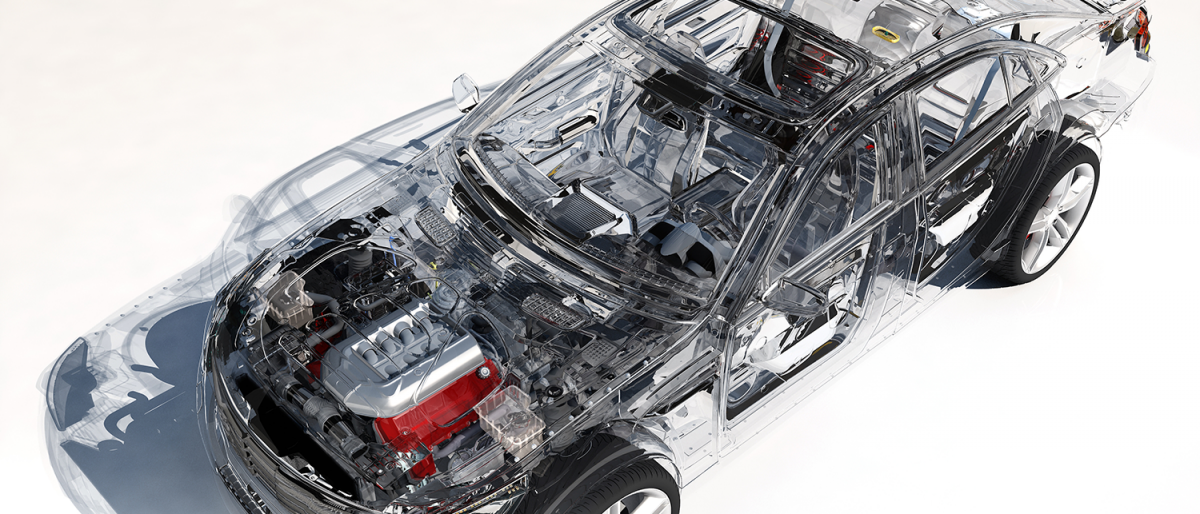

A commonly accepted ratio is that about one third of the power from the engine is lost through heat; another third is lost through inefficiencies in powertrain components; and the final third of the energy from the fuel is used to propel the vehicle. This shows where some opportunity to increase efficiency lies. In order to achieve this, it is important to know the allocation of efficiency losses so that the appropriate improvements can be made. Transducers are often installed in development vehicles to determine the location of power losses. Michigan Scientific has extensive experience making transducer measurements and turning production components into precision transducers.

The power input versus output of the internal engine components, transmission, and driveline, maps out the power consumption. A Wheel Force Transducer can be used to determine the overall output into the road. All other power mapping data is used to show the power that is used to make the vehicle move. In order to determine the power losses, the rotational speed and torque must be measured.

Engine Output Transducers

There are many different components that present an opportunity for engine output analysis; such as cooling fans, friction between moving parts, fuel consumption, oil and fuel pumps, belts, gears, lubrication, and more. Transducers can be made from, or applied to, the internal components and are used to measure the engine output. In an automatic transmission vehicle, a transducer can be made by applying strain gauges to the flexplate to measure torque. The data can be monitored using Michigan Scientific slip ring assemblies or telemetry solutions. Similar techniques can be used for a manual transmission vehicle by installing a torque transducer on the flywheel. It is also possible to instrument the vehicle’s crankshaft by deep-bore gauging, a method of applying strain gauges into a deep bore in a component, and routing the signal wires to a slip ring assembly.

Transmission Driveshaft Instrumentation

While the flexplate transducer can be used to determine the input power to the transmission, driveshaft transducers are used to detect the output. The transmission output torque is measured with an instrumented transmission output shaft or instrumented driveshafts. By calculating the input power and the output, the overall transmission efficiency can be directly measured. The transmission output shafts are instrumented and the wiring is contained with in the shaft. The data is then brought out to a slip ring assembly mounted in the front of the transmission or telemetry can be used with either inductive or batter power. Major losses in a transmission can be due to torque converter efficiency, oil pumping and heat losses, viscous spin losses, gear, bearing, and seal losses.

Rear Axle Measurements

The vehicle driveshaft is what provides input torque to the rear axle where the output torque is divided between each driveshaft. The output torque can either be measured with axle shaft strain gauges, turning the production shaft into a precision transducer routed to a slip ring assembly or telemetry, or a wheel torque transducer can be used. Michigan Scientific Wheel Torque Transducers (WTT) measure the torque between the mounting hub and tire. The efficiency is then determined by comparing torque into the axle to the output measured by the WTT.

While there are many other aspects that influence fuel consumption, such as aerodynamic drag, tire rolling resistance, brake drag, bearing drag, and others; determining the power losses within the driveline of the vehicle is still an important part of vehicle design and development. Michigan Scientific has extensive experience in creating custom and production transducers to help with this type of testing. To learn more about how Michigan Scientific can help with vehicle development, contact an MSC engineer.