Testing Efficiency of Farm Equipment

Understanding the distribution of power in farm equipment allows engineers to optimize fuel efficiency and productivity in both diesel and electric farm equipment. Michigan Scientific produces precision testing instruments with the capability to measure power losses in nearly every system in a variety of farm equipment.

Michigan Scientific precision instrumentation can measure nearly any part of a system’s speed, torque, and temperature. These measurements can determine the amount of power distribution for each system. Knowledge of power distribution can help engineers find significant power losses. This is crucial when working to improve overall efficiency.

Electric Farm Equipment

As the push for electrification increases, every industry has been working on the feasibility of the transition. The agricultural industry has many significant hurdles before electric farm vehicles become viable options. Battery capacity and infrastructure are major problems for the agricultural industry at the moment. Optimizing the efficiency of the machine will be a crucial factor when considering the battery capacity. Significant testing will need to be done on every system in electric farm equipment to fully understand power distribution. Testing will need to be completed in a variety of normal field operations as well as specific test conditions.

Example Instrumentation in Combine Harvesters

Knowing the torque applied to pulleys and gears offers crucial insight into forces experienced during use. Michigan Scientific can instrument pulleys and gears, including the gear teeth, to test the speed, torque, and temperature they experience when in use. These instrumentation solutions are ideal for both long-term tests during general use and specific test conditions. Slip Rings are used for transferring data from the part to a DAQ system.

The elbow gearbox on an unloading auger is necessary for transferring harvested goods into a truck or cart. On a combine, the unloading auger adjusts its position to be over the transfer location, then gears power the auger to move harvested goods through the auger tube. Michigan Scientific instrumentation can test the speed, torque, and temperature of the elbow gearbox to see where improvements can be made. This data is can lead to increased durability and efficiency.

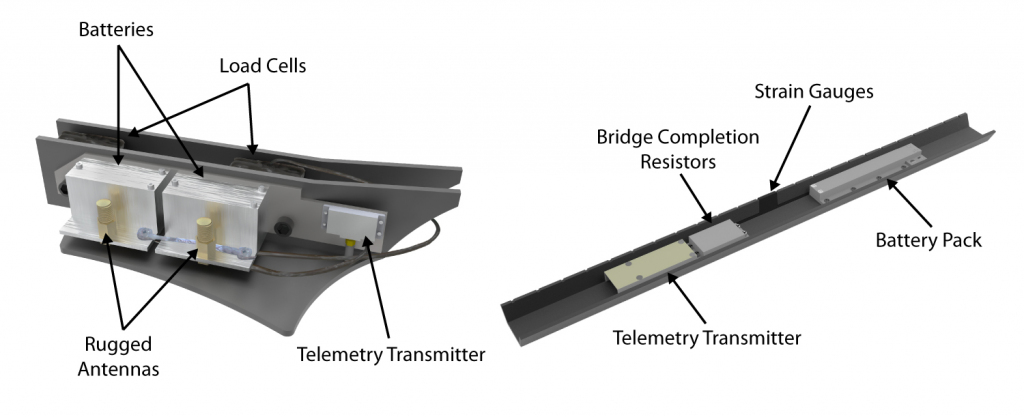

Michigan Scientific uses Multi-Axis Load Cells or custom gauging to measure forces experienced on moving components within an assembly. For example, Multi-Axis Load Cells can be mounted to rotor blades and feeder slats can be instrumented with custom gauging. The rugged design of our load cells ensures the ability to do field testing in the most difficult of conditions. Telemetry transmitters are used to transfer the data wirelessly from the load cell to a DAQ device.

Michigan Scientific specializes in designing and creating custom strain gauge transducers. Our engineers have expertise in gauging a wide variety of stock components. Michigan Scientific has completed a variety of instrumentation to help customers in the agriculture industry complete tests. We offer instrumentation capable of testing the efficiency of farm equipment while maintaining their strength and other characteristics as much as possible. To learn more about how Michigan Scientific can help with your instrumentation needs, contact us today!