Custom Strain Gauge Transducers

Michigan Scientific specializes in designing and creating custom strain gauge transducers. Our engineers have expertise in gauging a wide variety of stock components. We develop and fabricate vehicle component strain gauge transducers that measure vehicle suspension forces, powertrain torques, steering component forces, engine and motor loads, and braking torques on vehicles in the field. Michigan Scientific is able to help customers obtain accurate data on the forces experienced by a part, while maintaining its strength and other characteristics as much as possible. Michigan Scientific engineers and technicians have completed applications across several industries. We specialize in custom applications.

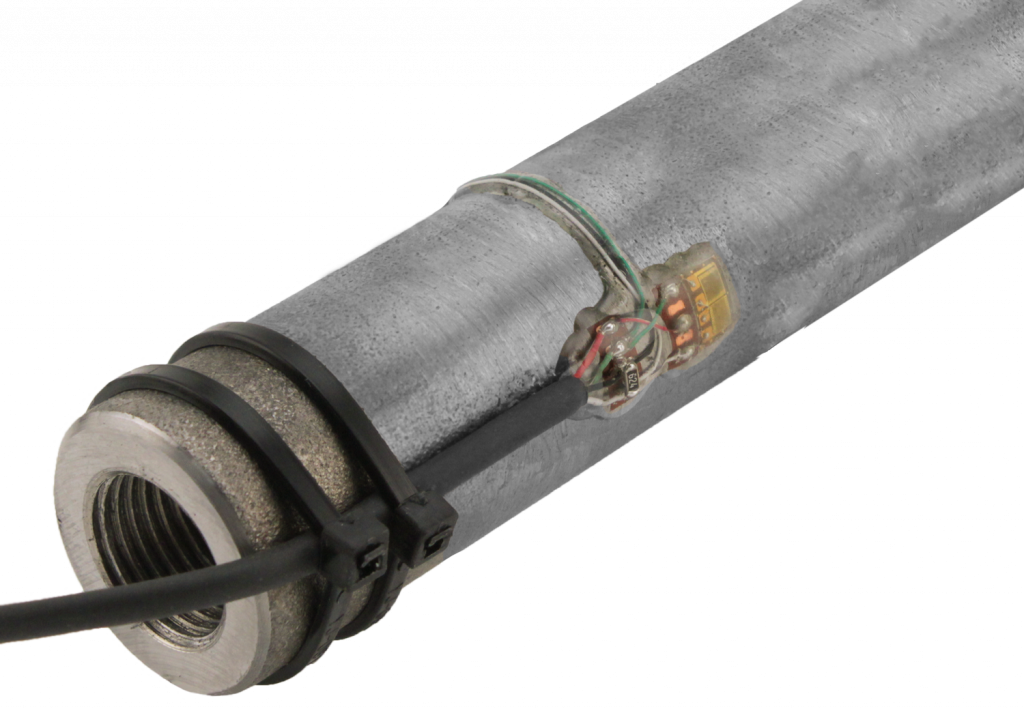

Shaft Torque Transducer

When applying strain gauges to a shaft, the goal is to obtain accurate data on the forces experienced by the shaft, while changing its strength and other characteristics as little as possible. The shaft then acts as a transducer itself. The strain gauged shaft, now a transducer, can be used in the same way as a standard shaft to measure the forces that occur in normal usage.

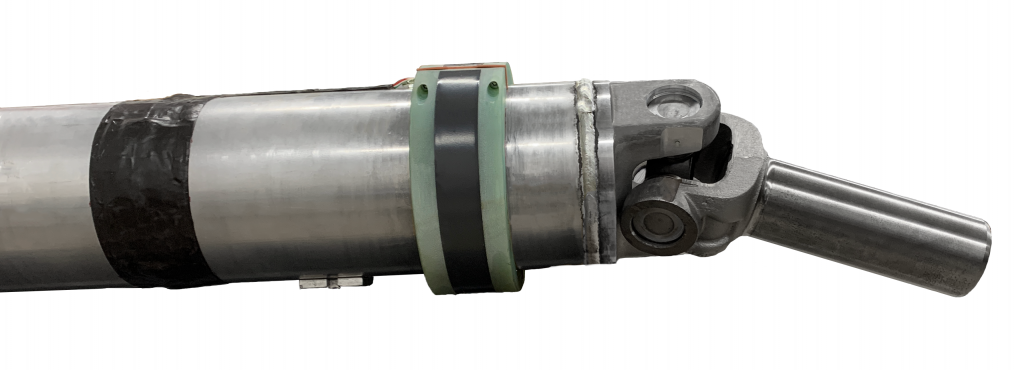

Half Shaft Strain Gauging

We strain gauge OEM half shafts to measure torque. The signals are amplified using our wheel instrumentation package (WIP) before they are transmitted by our ERT slip ring assembly. The ERT can provide speed and angular measurement signals too. The model PS-DC Remote Amplifier Control Unit controls the WIP and supplies power to the ERT.

Driveshaft Strain Gauging

Driveshafts can be gauged for torque and thrust. Michigan Scientific has developed a compensation bridge to reduce cross-talk from torque into the thrust bridge. After the shaft has been gauged, the data can be transferred from the shaft via telemetry or slip ring.

Crankshaft Transducer

One of the more complex examples of a custom strain gauge transducer is creating a crankshaft transducer. Strain gauges are applied on a standard crankshaft in order to measure engine torque. The wires are routed through the crankshaft to connect to spinning amplifiers and a slip ring or telemetry system mounted on the pulley at the front of the engine. In these applications, multiple channels of strain measurements are collected for analysis.

Axial Force Gauging

Our custom tie rod end transducers can measure the axial forces acting on the tie rod during steering. Tie rod end transducers can replace the inner or outer tie rod end, based on customer needs. The custom tie rod transducer does not take up any additional space underneath the vehicle and no modification to the vehicle is required. Almost all tie rods can be made into custom tie rod transducers.

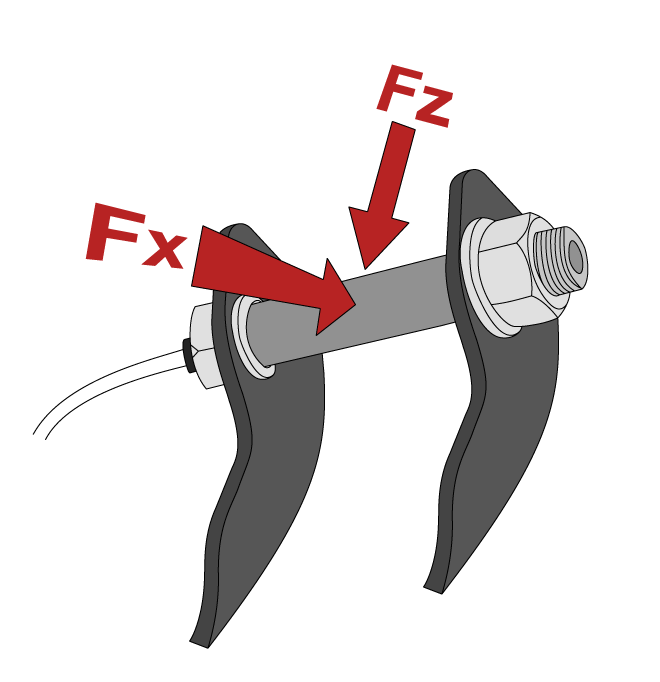

Shear Pin Transducer

Each application is custom designed to fit your application. The transducers are all machined from transducer-grade stainless steel and have a weatherproof coating. Our shear pin transducer is suitable for in-field data collection in addition to laboratory test setups. The shear pin transducer is easily adaptable to a wide variety of applications, is designed to not change the position of other vehicle components, and requires minimal modification to other parts.

Check out our Common Custom Transducers blog for more information on how we instrument parts to be used as transducers.

On-Site Strain Gauging

Michigan Scientific is capable of installing strain gauges on-site, at customer locations. Both component and structural applications can be instrumented for measurement and analysis. The customer’s components can be instrumented and data recorded to support a wide range of test and development activities. Components can be recorded during the manufacturing processes or in-service use. Michigan Scientific also has experience instrumenting structural beams for deflection and stress testing.

Instrumentation applications range from circuit board instrumentation for monitoring stress, thermal chamber door panel monitored for deformation during manufacturing, and fully instrumented industrial sized drive shafts. In the large drive shaft application, torque, acceleration, and rotational velocity were measured on a 16 inch diameter drive shaft of a large cement plant ball mill. Michigan Scientific also collected and analyzed the data from this project.

Michigan Scientific also uses decades of experience to install strain gauges in holes up to six inches deep and with a minimum diameter of 0.5 inches.

Data Acquisition and Reporting

Michigan Scientific provides on-site and remote data acquisition services for recording instrumented components under test. Additional data processing, analysis, and reporting services are also offered.