Measuring efficiency is important for the development of any vehicle, but when it comes to Class 8 electric vehicles efficiency can quickly determine the feasibility of the vehicle for potential buyers. With a long charging time, few charging stations large enough to accommodate a class 8 vehicle battery, and many miles to travel each day, it is paramount to produce the most efficient vehicle possible to maximize its range on a single charge. Michigan Scientific Corporation makes several products to test electric powertrains and axles to ensure maximum efficiency when measuring torque and other variables on class 8 electric vehicles.

Road Testing for Class 8 Electric Vehicles

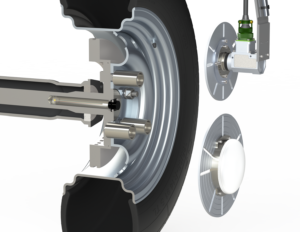

Michigan Scientific’s TWHR2000 Truck Wheel Torque Transducer assembly

Michigan Scientific Wheel Torque Transducers (WTTs) can be used to measure the drive and braking torque on class 8 electric vehicles. Using a WTT, the efficiency can be measured by comparing torque into the axle to the output measured by the WTT. Michigan Scientific’s TWHR2000 Truck Wheel Torque Transducers are ideal for measuring small variations in wheel torque on highway trucks.

Various parts of the drivetrain can be instrumented for tension and compression to measure bearing preload. Additionally, a Michigan Scientific End of Shaft Slip Ring Assembly can measure the wheel speed and position. Michigan Scientific Slip Ring Assemblies and Wireless Telemetry Systems can be used to obtain useful axle measurements. On class 8 trucks and other vehicles with solid axles, the space to mount a slip ring or telemetry system is limited. In this case, deep-bore gauging can be used to measure inside the axle. A production axle can be instrumented by drilling through the shaft and applying strain gauges within the bore. The signal wires are then routed to a slip ring or wireless telemetry system that is mounted outboard of the vehicle wheel. In these applications, the signal can be routed through either a slip ring or a wireless telemetry system.

Lab Testing

Deep-bore gauging an axle with telemetry

Using deep-bore gauging on axle shafts in a lab testing environment can also be effective. A dynamometer, or dyno, can be used to measure the torque and RPM of the axle. Michigan Scientific’s Wireless Telemetry Systems are best suited to this application. The non-contacting digital wireless link used in these systems means the telemetry system does not wear out even after prolonged use in a dyno lab testing environment.

Class 8 electric vehicles are hitting the roads, and Michigan Scientific products can ensure that those vehicles are prepared to keep pace with other class 8 vehicles and go the distance required of them everyday. To learn more about how Michigan Scientific can help with electric vehicle or class 8 vehicle development, contact an MSC representative.