Michigan Scientific specializes in designing and creating custom strain gauge transducers. Our engineers have expertise in gauging a wide variety of stock components. We develop and fabricate vehicle component strain gauge transducers that measure vehicle suspension forces, powertrain torques, steering component forces, engine and motor loads, and braking torques on vehicles in the field. Michigan Scientific is able to help customers obtain accurate data on the forces experienced by a part, while maintaining its strength and other characteristics as much as possible. These can be used to measure the loads that occur in normal usage, as well as benchmarking current designs, new design validation, and FEA/CAE validation.

Half Shaft: Torque and Speed

Michigan Scientific often gauges and calibrates OEM half shafts for torque. We can also provide speed and angular rotation measurements. Michigan Scientific commonly instruments half shafts with two different methods, depending on the customer requirements and space available.

The first method is to strain gauge the center of the half shaft, and then connect the gauges directly to inboard Wireless Telemetry (TEL-SC, CBT-mini, or CIT) or a Tubular Slip Ring Assembly (B7-T-1.2W).

Clamping Battery Telemetry (CBT-mini) on Half Shaft

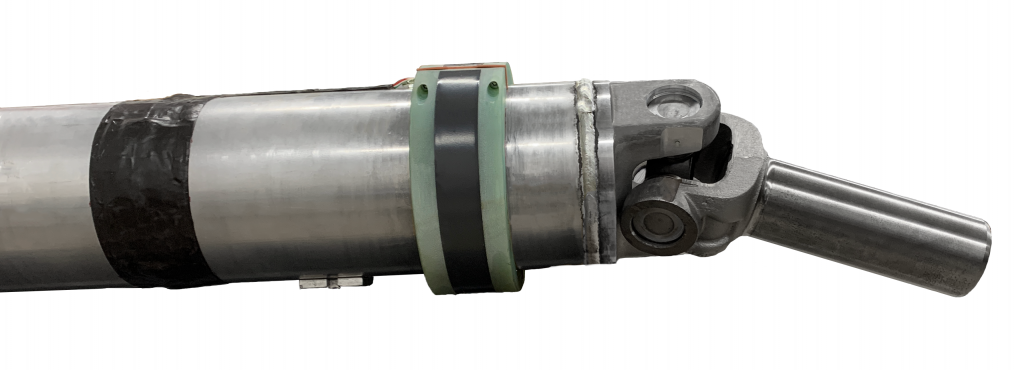

Gauged Half Shaft and WIP

Telemetry Wheel Package

The second method is to strain gauge the center of the half shaft, then route the wires through the CV joint to the end of the half shaft for connection to outboard slip ring or telemetry package. MSC can embed a small connector in the end of the shaft for convenient connection to the strain gauge bridge. Our rugged amplified outboard slip ring and encoder package consists of our Wheel Instrument Package (WIP), ERT slip ring assembly, and PS-DC power supply. This package provides high resolution wheel speed and angular position in addition to half shaft torque.

The low-profile outboard telemetry package is our Telemetry Wheel Package which is powered by a replaceable 9 Vdc battery.

Drive Shaft: Torque and Thrust

Michigan Scientific often instruments drive shafts for torque and thrust. We can strain gauge and calibrate drive shafts to measure torque to the vehicle’s rear axle. Thrust measurements of drive shafts are notoriously difficult to make accurately due to low strain gauge output and crosstalk from torque. However, Michigan Scientific has developed a special method to significantly reduce cross-talk into thrust channel to obtain an accurate measurement.

The drive shaft strain gauges can be connected to either Michigan Scientific Telemetry (TEL-SC, CBT-mini, or CIT) or Tubular Slip Ring (B4-2W (torque), B6-2W (torque and thrust), or B6-2W/AMP-SG2 (torque and thrust with amplifiers)). Michigan Scientific provides a complete package including strain gauging, installation of slip ring or telemetry, and system calibration.

Split Collar Telemetry on Drive Shaft

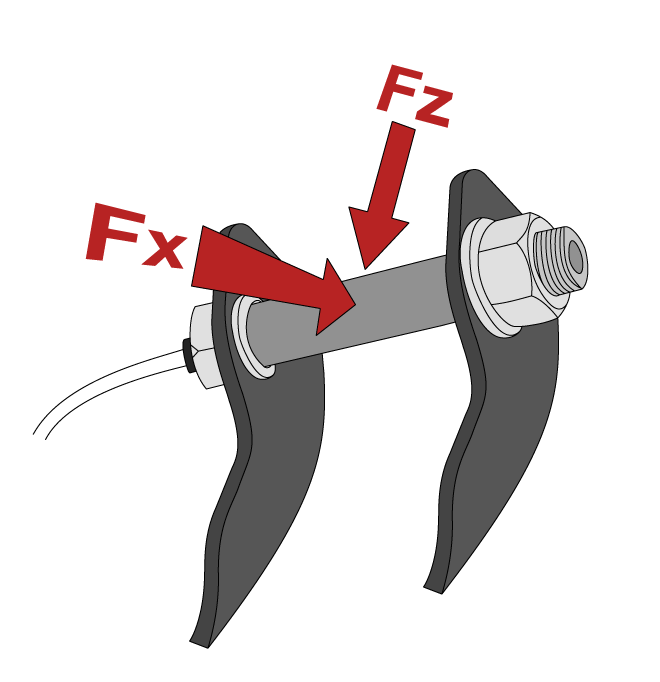

Shear Pin at a Bolted Joint: Forces in Joints

Shear Pin Transducer

Michigan Scientific’s shear pin transducer is designed and calibrated to measure perpendicular forces in bolted or pinned joints. This product is a strain gauge-based transducer which replaces a production bolt or pin. Each transducer is custom designed to fit your application. The transducers are all machined from transducer-grade stainless steel and have a weatherproof coating. Our shear pin transducer is suitable for in-field data collection in addition to laboratory test setups. The shear pin transducer is easily adaptable to a wide variety of applications, is designed to not change the position of other vehicle components, and requires minimal modification to other parts. They have been used to measure damper forces between the strut and lower control arm of a vehicle, and to measure suspension loads into the chassis at the locations where the control arms mount to the frame. Shear pins can also be used to measure forces into the transmission and engine mounts or isolators. We have designed transducers to replace bolts as small as M12 and transducers with load ratings over 17,000 lbs (7,700 kg). All shear pin transducers are designed to minimize crosstalk between channels and have high strain output, which provides good signal-to-noise ratio.

Tie Rod End: Axial Force

Tie Rod End Transducer

Our custom tie rod end transducers can measure the axial forces acting on the tie rod during steering. Tie rod end transducers can replace the inner or outer tie rod end, based on customer needs. The custom tie rod transducer does not take up any additional space underneath the vehicle and no modification to the vehicle is required. Almost all tie rods can be made into custom tie rod transducers.

Tie rod end transducers may be used in conjunction with other transducers to find inefficiencies or unanticipated forces within the steering system. Using a Steering Wheel Transducer and a tie rod end transducer, you could find inefficiencies in the steering gear box. Tie rod end and Wheel Force Transducer combinations could reveal unanticipated forces and moments experienced by the tie rods.

Ball-Joint: 3 Axis Ball Joint Forces

Ball Joint Transducer

One of the more complex examples of a custom transducer is a Ball Joint Transducer. Strain gauges are applied on a standard ball joint from a vehicle suspension system in order to measure the orthogonal ball joint forces. This transducer measures vertical, lateral, and longitudinal ball joint forces. The transducer is designed to function reliably in a harsh, real world environment with only minor changes in the normal configuration and operation of the ball joint. The strength of the production part is not reduced in any way. Therefore, the load capacities of these transducers are identical to those of the standard part.

Michigan Scientific manufactures these transducers (both upper and lower ball joints) for a variety of vehicle suspension systems. All units are completely weatherproof and temperature compensated to ensure stable output throughout a wide temperature range.

Engine Crankshaft Measurements

Gauged Crankshaft

Common engine crankshaft measurements include gauging near the main journal bearing, making bending measurements, or gauging strain in highly stressed locations, such as the fillets of the throws (pins). Typically, it is desirable to measure the output torque from the crank near the main journal bearing at the flywheel end of the crankshaft. This is usually the main measurement to which all other measurements are correlated. Making this torque measurement also allows for better study of the overall drivetrain because it is a direct torque measurement into the transmission.

Each application is unique since engine types vary greatly. MSC has provided crankshaft instrumentation services for applications ranging from small motorcycle engines to large 12-liter engines. Testing can be performed with the engine in the vehicle or on a dyno, but the instrumentation configuration will vary depending on the space available.

Michigan Scientific applies the gauges to the production shaft at the MSC facility. The signal wires from the gauges are routed to a slip ring assembly or wireless telemetry system. These rotating signal transmission products are ideal for communicating the signal from the strain gauges to the data acquisition. It is also common to mount a slip ring and amplifier package to the engine damper. Using a slip ring for signal transmission also allows for the rotational speed and angular position of the crankshaft to be measured. All of this data is crucial in engine and crankshaft studies.

Michigan Scientific engineers and technicians have completed applications across several industries. We specialize in custom applications. Our broad array of experience with gauging allows us to accomplish accurate measurements in difficult applications. We have been successful gauging small components in both noisy areas and limited spaces. To inquire about custom transducers and to see how Michigan Scientific Corporation can help you, contact a Michigan Scientific Engineer.