Michigan Scientific slip ring assemblies are the first choice for making connections to strain gauges, thermocouples, ICP accelerometers, RTDs and other sensors in rotating applications. Michigan Scientific Slip Ring Assemblies use high quality materials, making them compatible for transferring ethernet signals. A slip ring assembly is ideal for maintaining communication with, and supplying power to, PLCs and other electronic equipment used in rotational applications in the automation industry and robotics.

Features

- End of shaft and tubular models

- Weatherproof and Non-Weatherproof models

- Rugged stainless steel construction

- Lightweight and compact

- Permanently lubricated bearings

- Various connection options available

- An optional encoder available in certain models

Overview

A slip ring assembly is used to connect to sensors, such as strain gages, thermocouples, accelerometers, and others, on rotating equipment to data acquisition. Michigan Scientific Slip Ring Assemblies use high quality materials, making them compatible for transferring ethernet signals. As the equipment is rotating, it is necessary to form a connection that allows the sensors to still rotate with the equipment, but not disrupt the stationary data acquisition.

A slip ring assembly has a rotating component, called a rotor, and a stationary component, called a stator. The rotor is often attached to the rotating component, such as a shaft, with connections to the sensors. The signal from the sensors pass through the rotor and to the stator, where the stator is stationary and connected to the DAQ. A slip ring assembly allows for rotating signals to come to a stationary mean of collections.

Because of their simplicity, slip ring assemblies are the first choice for making connections in rotating applications to strain gages, thermocouples, ICP accelerometers, RTD’s and other sensors. They are also the primary choice for maintaining communication with and supplying power to PLC’s and other electronic equipment used in rotational applications in automated industry and robotics. For most applications no extra equipment is required than what would be necessary for a stationary application. It is also much easier to troubleshoot and diagnose signal noise and quality issues than in a system that is utilizing more complex equipment.

Slip Ring Assembly Design and Manufacturing

Michigan Scientific has been designing and manufacturing slip ring assemblies since 1960. We produce thousands of standard assemblies per year. The standard units range from 4 to 36 connections. Our slip rings assemblies are instrumentation quality units designed to be used with strain gage, thermocouple and other sensor signals. In addition to our standard assemblies, we design and manufacture hundreds of custom slip ring assemblies per year.

We have manufactured assemblies for the following custom slip ring applications:

- Sealed for operation submersed in oil

- Used in hard vacuum, some outer space applications

- 240 channel assembly for NASA used to test centrifugal compressors

- Weatherproof, sealed to operate in all weather applications

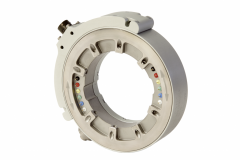

- Assemblies with thru holes used to mount over rotating shafts

- 52 circuit assembly for NASA used for helicopter wind tunnel tests

- Assemblies with internal encoders and resolvers

- Units with internal tachometer generators

- Units with customer specified connectors

- Units with both instrumentation and power circuits

We have a complete engineering, design, manufacturing and testing facility that enables us to produce the highest quality slip ring assemblies.

What makes MSC Slip Ring Assemblies Unique?

Michigan Scientific Corporation slip ring assemblies set the industry standard for ruggedness, durability, and efficiency of design. Our assemblies are primarily designed for use in vehicular testing. This testing tends to be very rigorous and demands that the slip ring assemblies be able to not only survive a wide range of dynamic testing environments, but also provide dependable, instrumentation quality signal connection under demanding conditions. Meeting the needs of such demanding applications has resulted in the development of quality slip ring assemblies and accessories that are a preferred choice for any application that requires a quality instrumentation grade slip ring assembly.

What can MSC Slip Ring Assemblies do for me?

In many applications, it is important to know the rotational speed and position of the part being tested. Since the rotor of a slip ring assembly rotates directly with the rotating portion of the application, the slip ring assembly provides an ideal platform for the installation of rotational sensors. We have chosen and developed encoders, resolvers and encoder electronic packages that are both accurate and durable. Through imaginative design and attention to detail, we have been able to package these sensors within the housings of several of our assemblies, creating durable, compact assemblies.

How can I be sure MSC Slip Ring Assemblies will work for my application?

Michigan Scientific Corporation was incorporated in 1960. Since then we have produced slip ring assemblies for a wide variety of applications, from industrial automation to aerospace applications; from heavy construction and agricultural equipment testing, to high performance motorcycle development. We have considerable experience in meeting the demands of difficult slip ring applications. We are confident we can meet your needs too.

Documents

Videos

Related Blog Posts

Models